Quick Overview:

Concrete failure rarely shows up all at once. It starts with small warning signs most people miss. This guide breaks down the early red flags GCs see first, from cracking and settlement to drainage and pour-day mistakes, and how catching them early saves time, money, and reputation.

Concrete Rarely “Fails Overnight”

Concrete almost never wakes up one day and decides to fail. It gives warnings. Quiet ones at first. Easy to miss if you are rushing a schedule or trusting that someone else is watching it. After twenty years in Florida concrete, we can tell you this straight. Most failures start small, sometimes weeks or months before anyone wants to admit there is a problem.

Hairline cracks. Slight settling. A finish that just does not look right. None of those alone mean disaster. But together, or ignored, they turn into change orders, delays, finger-pointing, and sometimes lawyers. We have seen slabs torn out that could have been saved. We have also seen projects pushed forward when they should have stopped, and everyone paid for it later.

General contractors usually see these signs first. Not inspectors. Inspectors show up for snapshots in time. GCs live on the site. They walk the slab every day. They hear the crew complaints. They notice when something feels off. The problem is not lack of warning. It is hesitation to act on it.

Concrete failure costs more than money. It costs trust. Owners lose confidence. Schedules blow up. Subcontractor relationships strain. And in Florida, where soil, moisture, and heat work against you every day, ignoring early signs is gambling.

Concrete talks. Quietly. The smart GC listens early, not after the slab starts talking loud.

Cracking That Doesn’t Look “Normal”

All concrete cracks. Anyone telling you otherwise has not poured enough of it. The key word is normal. Hairline shrinkage cracks during curing are expected. They usually run straight, shallow, and stay tight. Structural cracks are different. They move. They widen. They follow stress paths, not convenience.

Map cracking often shows up as a spider-web pattern on the surface. That usually points to surface issues like over-finishing, excess water, or rapid moisture loss. Diagonal cracks, especially at corners, openings, or column pads, raise bigger concerns. Those cracks often point to settlement, restraint, or load issues.

Timing matters. Cracks that appear during cure often tie back to finishing and curing mistakes. Cracks that show up months later usually point to soil movement, drainage problems, or reinforcement issues. We have seen slabs that looked fine at turnover, then cracked badly after the first rainy season. Florida soil does not forgive poor prep.

A red flag we watch for is cracking that does not follow joints. Joints exist to control cracking. When concrete ignores them, something else is wrong. Either the joints were placed wrong, cut too late, or the slab is moving more than expected.

GCs should not brush this off as cosmetic. Early crack patterns tell a story. Ignore the story, and the ending is rarely good.

Uneven Surfaces and Early Settlement

Low spots. Birdbaths. Slight dips you feel when you walk the slab. These are not just finish problems. They usually start below the concrete. Base prep, compaction, moisture control. All the unglamorous work that makes or breaks a slab.

When we see early settlement, we think about what the soil was doing that day. Was it too wet. Was fill placed too thick. Was compaction rushed. In Tampa and surrounding areas, sandy soils shift fast when water moves. If drainage is not right, settlement shows up early.

The phrase “we’ll grind it later” is one of the biggest red flags in concrete work. Grinding hides symptoms, not causes. If the slab is moving, grinding buys time, not stability. We have seen slabs ground flat, only to settle again months later.

Unevenness also affects load distribution. Equipment, racking, vehicles. Loads find low points. Stress concentrates. Cracks follow.

A GC who notices early settlement should slow down and ask questions. Not patch and hope. Once finishes go in, access disappears and fixes get expensive.

Spalling, Flaking, and Surface Dusting

Surface breakdown during curing is never a good sign. Spalling, flaking, or dusting usually point to problems in the mix or the finishing process. Too much water. Over-finishing. Weak surface paste. Sometimes all three.

Over-finishing traps bleed water and air at the surface. When that layer dries, it is weak. It flakes. Dusting shows up as fine powder under foot traffic. That is concrete telling you the surface is not durable.

We see this often when crews chase a slick finish in hot weather. Florida heat accelerates set time. Crews panic. Water gets added. Trowels come out too early. The surface looks good for a few days, then starts breaking down.

Surface failure often predicts deeper issues. If the top inch is weak, what about the rest of the slab. Especially in structural or industrial applications, surface integrity matters.

GCs should document this early. Photos. Notes. Mix tickets. Because once traffic starts, everyone will argue whether the damage was caused or inherent. Early evidence matters.

Discoloration and Inconsistent Finish

Concrete color tells stories. Dark patches. Light patches. Mottled areas. Sometimes it is harmless. Sometimes it is not. Uneven curing, moisture differences, or inconsistent placement all show up in color.

Dark areas often hold moisture longer. Light areas may have dried too fast. Mottling can point to uneven finishing or different batch properties. On decorative or exposed slabs, this becomes a big issue fast.

Appearance problems become structural concerns when tied to moisture. Uneven moisture means uneven shrinkage. Uneven shrinkage means stress. Stress finds release through cracks.

We have also seen discoloration tied to contamination. Mud tracked onto the slab. Rainwater pooling during cure. Curing compound applied unevenly.

GCs should not assume color will even out. Sometimes it does. Sometimes it gets worse. The key is understanding why it happened before moving forward.

Excessive Bleeding or Standing Water

Bleeding is normal. Excessive bleeding is not. When water rises to the surface and sits there, the mix is telling you it is too wet or poorly proportioned.

Standing water delays finishing. It weakens the surface paste. It increases shrinkage. It reduces durability. In Florida humidity, excessive bleed water also increases the risk of surface scaling later.

Signs of trouble include bleed water reappearing after finishing starts, or water pooling in low areas for long periods. That usually points back to mix design or last-minute water additions on site.

Long-term risks include reduced strength, increased permeability, and surface failure. Bleed water creates capillaries. Capillaries move moisture. Moisture moves problems.

GCs should never ignore excessive bleeding. It is one of the earliest and clearest warnings concrete gives you.

Delayed Strength Gain

Break tests do not lie. When cylinders miss strength targets, something is wrong. Slow strength gain often points to excess water, low cement content, or curing issues.

The dangerous phrase here is “give it more time.” Sometimes time helps. Sometimes it does not. Weak concrete does not magically become strong concrete.

We have seen slabs held up waiting for strength that never came. Meanwhile, schedules slipped, trades stacked up, and pressure mounted to proceed anyway.

GCs should push for answers, not excuses. Mix design review. Batch records. Cure conditions. Temperature logs. Strength issues deserve immediate attention.

Joint Problems Showing Up Early

Joints are supposed to control cracking. When joints fail, slabs fail. Early raveling edges, spalling, or random cracking between joints point to layout or timing problems.

Late saw cuts are a common cause. Concrete cracks when it wants to. Not when the schedule allows. Poor joint spacing also forces cracks to find their own path.

Once joints fail, repairs are ongoing. Fillers fail. Cracks widen. Water gets in. Problems compound.

GCs should take joint layout seriously. It is cheap insurance compared to slab replacement.

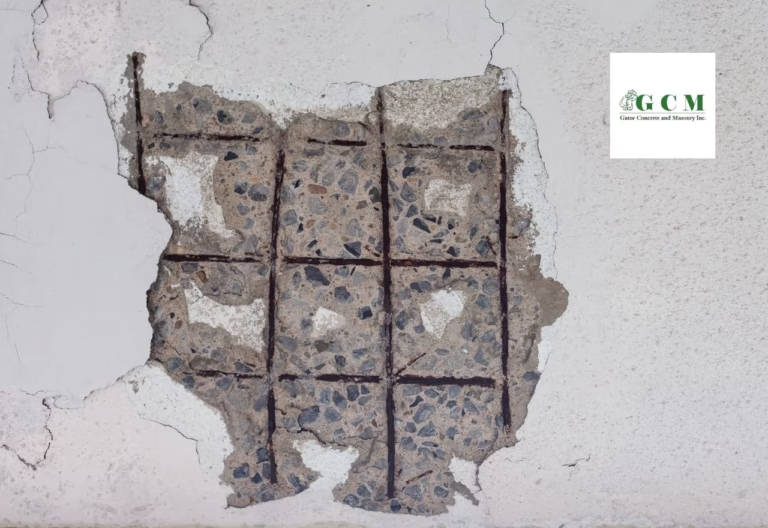

Rebar and Reinforcement Issues

Rust staining appearing early is a warning. It usually means improper cover. Reinforcement too close to the surface. Or concrete too permeable.

Rebar issues often stay hidden until cracks expose them. Then it is too late. Poor placement, chairs knocked over, or missing steel all show up later.

We always stress inspection before the pour. After the pour, options disappear.

Drainage and Moisture Red Flags Around the Slab

Concrete failure often starts outside the concrete. Standing water near foundations. Poor drainage. Soil movement. Hydrostatic pressure.

In Florida, water is relentless. If it cannot move away, it will move soil. Slabs follow.

GCs should watch site drainage like a hawk. If water ponds today, cracks show up tomorrow.

Warning Signs During the Pour You Can’t Ignore

Rushed placement. Poor vibration. Crews skipping steps. Last-minute mix changes. These are real-time warnings.

Once concrete hits the ground, decisions matter fast. Bad decisions live forever in cured concrete.

GCs need the authority to slow things down. Quality beats speed every time.

When to Stop the Job and Ask Hard Questions

Stopping a job feels risky. Not stopping it is riskier. When signs stack up, pause. Document. Ask for answers.

Early intervention saves schedules and reputations. We have seen it firsthand.

Don’t Patch Over Problems. Bring in Gator and Fix It Right

If you are a GC in Tampa or surrounding areas and something feels off with your concrete, trust that instinct. Gator Concrete and Masonry Inc has spent 20 years working Florida soil, Florida weather, and Florida schedules.

We handle grading, drainage, ADS drains, underground retention drains, foundations, concrete, block walls, demolition, tree stump removal by dig-out, site cleaning, and sand removal. Yes, even the beach sand showing up in streets and homes.

Contact Gator Concrete and Masonry before small signs